Water Management

We will generate positive impact by producing more beer with less water in order to protect our core raw material and to ensure that society’s needs are safeguarded in the future also

Water is our core raw material in all stages of our value chain from the production of barley and hops to beer manufacturing and packaging. Water which also constitutes the majority of our product content is becoming an ever diminishing resource due to population increase and climate change. Therefore, securing water resources which have been identified as a major risk factor in our corporate risk management model also is important not only for sustainable production but also from a view point of social needs.

Our Goal:

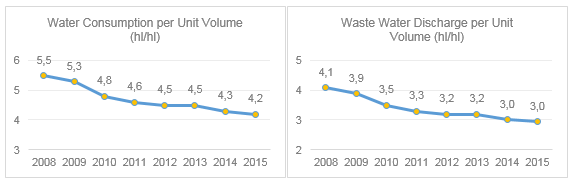

For the first term of Anadolu Efes Positive Impact Plan between 2008 and 2015, we had aimed to reduce our water consumption and wastewater discharge per unit product by 35% compared to 2008. Changes occurred in market structure made negative impacts on our goals although we have achieved a significant performance. Despite all, we have achieved this target 68% for water consumption, 86% for wastewater discharge by 2015.

For 2020, we aim to reduce water consumption and wastewater discharge per unit product in breweries by 30% compared to 2008.

Water Management Structure:

There are three main policy documents laying down the basic principles of Anadolu Efes Global Water Management. Anadolu Efes Code of Conduct sets out our general corporate principles in environmental and water management as in every other area. Anadolu Efes Environmental Policy lays down the basic principles of environment management within which water management is defined as a main topic. Additionally, due to the role water management plays on our sustainability performance, Anadolu Efes Water Policy is disseminated as a separate policy document. Anadolu Efes Water Policy and the water management system and standards it foresees are followed up in all Anadolu Efes country operations.

In accordance with Anadolu Efes Water Policy, global water management entails two main dimensions, namely, water consumption and wastewater management. In general, on these issues, which make up the company’s water footprint, the general corporate strategy and commitments are determined at the top management level. The strategic direction that has been developed is transformed into long term plans and global and local action plans designed to realize these by the Supply Chain Directorate which is represented on the Executive Board. Country operations are responsible for putting these action plans in place.

The performance realized through country operations are followed up within the framework of the defined quantitative objectives. The performance, which is followed up by the indicators included in the individual performance objectives of the relevant managers at every level are also factored in the remuneration system.

The Sustainability Champions Team; responsible for the direction of the strategic structuring and operational processes of the Anadolu Efes program, assumes an effective role on the issue of water management as well. The team, where the core functions of Anadolu Efes are represented, is significant as it reflects the multidisciplinary approach to the management of this issue requires. Decisions taken here provide input for the action plans developed by the Supply Chain Directorate.

Systems that have been put in place play a significant role in implementing water management effectively and systematically. As in all other environmental issues, processes followed in water management have been designed in compliance with the ISO 14001 Environmental Management System Standard. System assurance is achieved through periodic internal audits and independent audits carried out in accordance with ISO 14001 certification. Results obtained are periodically reported to country operations managers and relevant top management executives whereby areas of improvement are determined. In these areas, projects aiming to enhance performance are developed.

Protection of water resources is also a social responsibility. In this framework, Anadolu Efes has adopted the management principle of working with relevant stakeholders first and foremost with NGOs and initiatives working in the area of protection of water resources on a local, national and international level. To this end, the UNGC CEO Water Mandate we signed in 2014 is a global organization bringing together international companies working actively in the area of the protection of water resources. Within the scope of the principles laid down by this initiative, water management policies, systems and processes are developed, efforts aimed at the protection of water resources are carried out and the performance achieved is shared with the public through sustainability reports. On the other hand, as a member of WBCSD Turkey (SKD), Anadolu Efes leads the Water Work Group. Also, in our country operations, cooperation is developed with the relevant parties through work carried out on a local level in our country operations.

It is a fact that water resources are diminishing in parallel with the population increase and climate change. The production of agricultural products which are the core raw materials of Anadolu Efes is highly dependent on water. We regard the reduction of this dependence as a priority target in developing a sustainable future and through the R&D studies we have been undertaking for years within the framework of sustainable agriculture program, we grow barley and hops species that can be grown with a minimum water requirement in arid regions that will also reduce water requirement in beer production processes due to their characteristics. The new species we have developed as a result of these studies are being used in production with a high ratio of water consumption efficiency.

Water Management Initiatives in 2015:

• Anadolu Efes Turkey Istanbul Brewery, has converted cooling system of vacuum pump in bottle filling facility from open loop to closed loop system.. Through this initiative, 13.000 m3 of water is saved annually.

• Anadolu Efes Russia Kazan Brewery, used more efficient cooling tower for cooling of its high pressure air compressor, which resulted in 33.000 m3 of annual water saving.

• Anadolu Efes Kazakhstan Almaty Brewery achieved 12.000 m3 water saving by using semi-dry lubricants at bottle line conveyors instead of lubrication with water.

• Anadolu Efes Moldova Vitanta Brewery realized 3.000 m3 of annual water saving through recovering water from vacuum pump in bottle filling facility.